Procurement professionals and supply chain managers in the procurement process all have a mutual goal and that is, they are hellbent on saving costs with every obligation. How effective these efforts are is viewed as the standard by which they are measured in the industry. That is why they often turn to spend analytics solutions to reduce spend. However, spend analytics will not give you accurate stats and results if supplier and product data (across all relevant systems within a company) is not consistently managed.

So, what causes Procurement nightmares?

Supplier information is not captured in one central system: I would think it is quite critical to have supplier or vendor information captured in a system of integrated applications to manage the business and automate many back office functions related to admin, services, and human resources. However, it appears that some companies don’t see the importance of carrying all their eggs in one basket. It’s strewn across different applications and, as if matters were not complicated enough, some don’t bother to sync valuable info across company divisions.

Supplier identities are not consistent: To give you an example: The Johnson & Johnson Pharmaceutical Company could be the name of the supplier in one system, while Janssen Pharmaceuticals (which forms part of Johnson & Johnson) could be the supplier name in another system. Supplier names could be in different languages, etc. This can seriously mess up your reporting.

Supplier information changes all the time: Companies move and addresses change, they close down or change their name, merge with one another or acquire one another. Sometimes companies tend to focus on too many lines of business that they need to close down a few operational units to focus on the more profitable ones. Any changes to supplier information should be tracked for auditing and compliance purposes.

Suppliers are not paid on time: Procurement professionals work hard to build profitable supplier relationships. However, a cause for concern is the relationship between accounts payable and procurement. Suppliers have good faith in a business partnership that they will be paid on time and by not adhering to the arranged payment terms suppliers could question the partnership they have with a company. This causes unnecessary strain on the relationship that can lead to financial losses. That’s why there should be a good collaboration between accounts payable and procurement.

No automatic updates: When a global company, let’s stick to Johnson & Johnson, update their supplier information in their system, supplier information in all other systems of the organization is not necessarily updated on a global scale. Consistency is key! Keep supplier information accurate and consistent by using effective data management tools and keep supplier/procurement relationships professional. All of this will provide more visibility in your monthly reports and as mentioned before, effective data management and system integration is key to preventing these issues from surfacing.

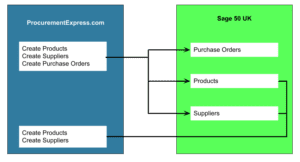

Invoices being received in Accounts Payable without pre-authorised purchase orders: Due to end users bypassing the process, as purchase orders are too time-consuming or inaccessible, fraudulent purchase orders could creep into your books. With a dedicated online purchase order management app, like Procurementexpress.com, it is easy to save company money and time, manage purchase orders + suppliers online and put you in control of company spend. Employees can load purchase orders and attach invoices from any device, managers can approve, reject or comment on purchase orders and get an instant view of budgets (even when on the road) and accounts payable departments get accurate and paperless expense tracking