A good relationship with your suppliers is just as significant as the products you sell or the services you provide.

These folks are more than people you pay for raw materials. They’re the gate-keepers to the farm-to-table produce your event company relies on. They’re the ones that source the best fabrics or the best price on spare parts–in short, suppliers make or break your customers’ experience.

Pretty heavy stuff, no?

Supplier relationship management (SRM) aims to improve the relations between the buyer and the supplier. Often, supply chain managers don’t foster these connections as best they can and don’t get the best price or the highest priority because they haven’t put in the time on those soft skills—connecting with the people you need to move your business forward.

[content_upgrade cu_id=”3537″]A Few Tips For Improving Supplier Relations — click to download this short checklist for building better relationships. [content_upgrade_button]Click Here[/content_upgrade_button][/content_upgrade]

1. Before Signing Anything, Check the Risks

Just like any relationship, don’t jump into any arrangement without first getting a taste of what’s in store. While smaller one-off purchases don’t matter so much, if you’re looking for a new supplier for the bulk of your materials, you need to be careful.

Ask the prospective supplier for references, work history, and their areas of expertise. Also, find out how they’d handle a crisis like a lost shipment or a data breach. Are their prices fair? Are they financially stable? Sure, the list is long, but failing to ask questions opens you up to risk. When tens or even hundreds of thousands of dollars are on the line, you want to do your homework.

Make sure they can provide good terms and can fill your orders promptly. Do they have the capacity to deal with your requests?

Don’t discount the supplier who doesn’t give you the lowest price. There may be other perks that matter more to your organization. For example, a company that offers fast delivery with a 100% guarantee–that’s a keeper. You can’t have business slow down in the name of a bargain, after all. Waiting for supplies puts your whole supply chain at risk–and by extension your business.

Don’t hesitate to call the references the vendor has provided and get more info. Know that a supply chain is as strong as the weakest link and if your vendor fails to deliver you risk late deliveries and lost money. Or worse, lost trust with your customers.

Suppliers are partners and as such, relationships depend on a whole lot more than the exchange of cold, hard cash. Instead, build loyalty and trust that works both ways.

[bctt tweet=”Suppliers are partners and as such, relationships depend on a whole lot more than the exchange of cold, hard cash” username=””]

That said, ensure your vendors have your back in the event of a real supply chain emergency. Someone who is being treated well will be more inclined to respond to requests that might force them to shift the day’s existing priorities. A well-managed supplier is a useful resource in attaining industry knowledge.

2. Relationships with Suppliers Must Be Mutually Beneficial

Building on our last point–treat your suppliers like partners. While, yes, everyone in the procurement/supply chain game emphasizes the power of the partnership, relationships must feel equal and mutually beneficial.

Like a good marriage, the buyer-supplier relationship must feel like it provides value to both parties. It shouldn’t follow a model where one party tells the other what to do, and the other sometimes listens or zones out.

You know, it’s the whole do unto others thing.

Instead, create a partnership where you collaborate with the vendor. This means communicating regularly about goals, asking for advice, and checking in about new products or innovations.

When the communication channels are open, both parties receive higher success rates. On the vendor side of things, they’ll work with a steady client instead of focusing their efforts on chasing down new prospects or smaller orders. On the buyer side, you’ll get consistency, quality, and reliability.

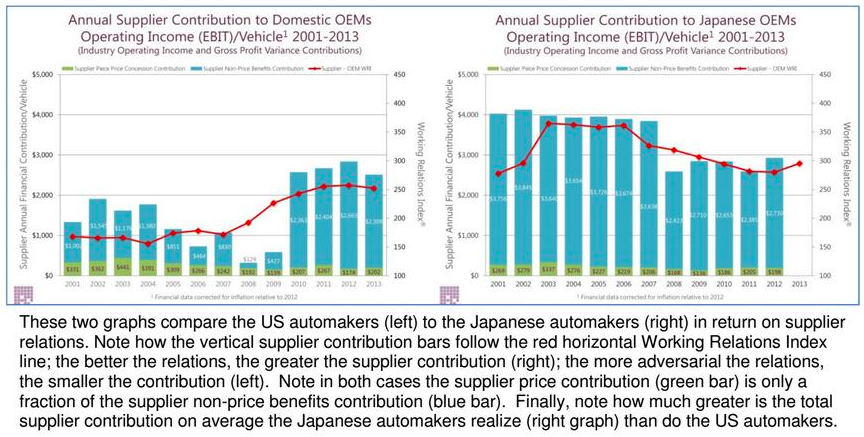

While this example below is a bit on the older side, it really lays out the benefit of opening up those channels of communication.

3. Plan Ahead

Was it Benjamin Franklin that said fail to plan, plan to fail? Honestly, we’re not sure, but the famous phrase remains true, especially in the world of supplier relations.

You don’t want to be the operations manager always putting in the call for a rush job; it makes you look bad.

Yes, emergencies happen, but if you’re continually calling your suppliers in a panic, asking for last-minute priority, the folks on the other end are going to get upset, fast.

Overnight orders and second-hand stress adds up. Part of having a positive relationship with your vendors is taking it upon yourself to keep abreast of inventory and upcoming projects. It takes being organized to mitigate some of the emergencies down the road. If you’re having trouble with this, hire someone who is detail-oriented and can run a tight ship.

4. Don’t Be a Flake–Be Sure to Pay On Time

If you don’t want to lose your suppliers, step one is making sure to pay them on time. This way, you will prove that you are a reliable customer and that you’re easy to work with. If for any reason you cannot make the payment on a date agreed, inform the supplier as soon as possible with the date on which they can expect the payment.

Suppliers, like anyone else, appreciate timely payments in exchange for their fast turnaround time. It’s the old golden rule, reimagined for supplier relations.

Still, failing to keep tabs on your budget or order statuses may hold things up. If you don’t know if goods were received, or even ordered, you’ll want to add some software solutions into the mix–like AP automation and digital POs.

This way, you’ll never lose an invoice and double order or lose track of amounts owed to various vendors. Also, the quicker you receive POs, the quicker you can receive product and make payments.

5. Detailed Agreements are Everything

If you plan on buying from a specific set of vendors on a regular basis, you’ll need to cover your bases. Supplier Relationship Agreements are essential. Get everything in writing that both sides need to consider the partnership a success. Items include pricing, delivery terms, payment terms, communication protocol, and service description. From there, both parties must sign to confirm they agree.

A well-crafted document will prevent misunderstandings down the road, laying out everything from processing payments to timeframe expectations.

Just one mistake in the agreement can open your business up for risks. Get multiple eyes on the document and consult with a lawyer, if needed. Be sure to cover every, single base.

[content_upgrade cu_id=”3537″]Learn to be a better customer–download this supplemental checklist for more supplier relations best practices. [content_upgrade_button]Click Here[/content_upgrade_button][/content_upgrade]

Final Thoughts

It is important to understand the reality of the engagements with your suppliers. By understanding this you will be more prepared to safeguard yourself from issues that could arise in the future. We can’t control the natural disasters, bankruptcies, and security breaches that can affect our business.

A positive relationship with your supplier means you can count on better products, lower costs and reliable manufacturing processes. The more your supplier understands your company and your customers, the better they’ll be able to assist with the products and advancements that can help you grow your business as they grow theirs.

Beyond being respectful to others and making your payments, you’ll want to find new ways to engage with these suppliers. This could mean regular lunch dates, trade show meetings or just a check-in email now and then.