The product price is the first (and often only) consideration when there’s a need for new resources in a business.

While many people are penny-wise when it comes to evaluating a quote, most don’t look beyond that initial fee. They focus so heavily on short-term savings that they neglect to take other costs into account.

But to stick to your budgets and run a tight financial ship, you must take a serious look at the hidden costs of things, too.

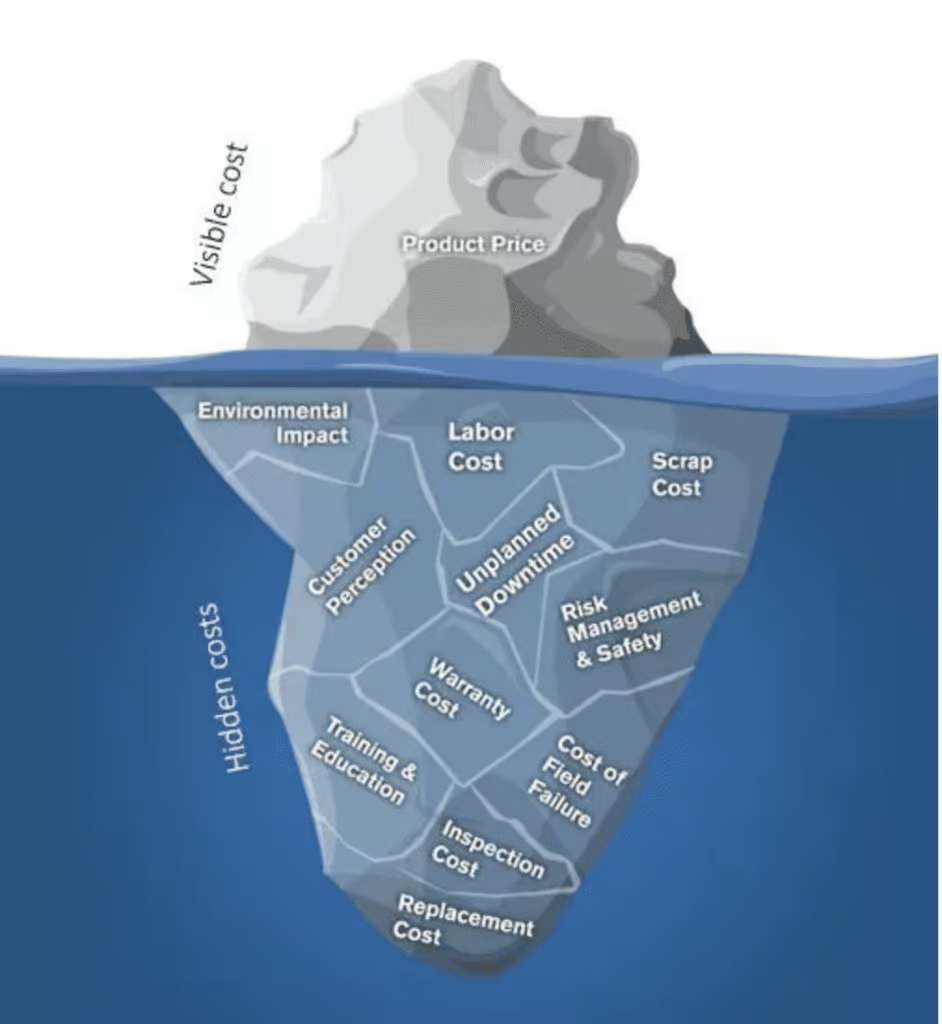

There’s a concept called the cost iceberg, which refers to the idea that, like an iceberg, the total cost of an item might not be evident at first glance. It’s a useful metaphor if you’re responsible for your company’s spending, as it will help you keep hidden costs to a minimum.

Above the surface are visible costs, that is, what the vendor quoted. But it doesn’t account for the value the purchase stands to add to your business, how much you’ll pay for repairs, or what you’d lose if the system failed.

Under the surface are indirect costs such as freight, delivery, installation, and training that collectively represent the total cost of ownership (TCO). It’s imperative to have the full picture before purchasing anything.

Below, we’ve rounded up the things that the purchase price alone will never tell you and can play havoc with your bottom line if ignored.

Installation

Installation costs might not be included in an initial estimate. If the solution calls for installation, it’s vital to consider the set-up fees and how long the process will take.

Be sure to ask the vendor if the installation is included in the quote or if you’ll need to pay an additional fee.

You might also consider whether the installation is something that can be done in-house. If so, what are the costs of delegating the task to an employee versus outsourcing the job to a third-party technician?

Finally, it’s worth looking at the complexity of the setup. Will you be able to swap out parts and make changes yourself? If you need to contact a third party every time something needs to be updated or repaired, the purchase might not be worth the effort.

Delivery

Even if the initial price looked good, you might get stuck with a bill twice the amount of the initial quote if the delivery costs were excluded.

Communication with the vendor is key.

Both the buyer and seller need to be clear on who is responsible for what, including insurance, freight, and customs documents. As the buyer, you should ask detailed questions about shipping terms and total cost as it pertains to the product and delivery.

Training

Does the item in question require training? And if so, is it included in the seller’s price?

If it requires training, your contract should outline who will be offering the training, how many sessions are included in the price, and whether ongoing training is needed. It should also be stipulated whether it is included in the initial quote or not.

Whether you’re purchasing a sophisticated software suite, an IT solution, or new equipment, you’ll need to look at the training and onboarding efforts associated with the purchase.

In some cases, you might have to pay extra for a trainer to come to your facility to show your staff how to use the new equipment. This might mean paying them for extra hours or taking time away from daily operations to learn something new.

If the purchase is software or computer equipment, consider the ease of use as much as the price. A complicated solution is going to require much more training and may lead to costly mistakes down the road.

Operation & Labor

Is this purchase something that’s going to increase labor costs? Before you sign any contracts, know your exact operation cost. Operation labor is sometimes overlooked during the supplier evaluation phase, but it should be given priority.

Savvy buyers understand that they must weigh operation labor against the initial quote. The cheapest solution, of course, won’t look so attractive when you’re adding materials and labor.

Operation labor also extends to other areas, such as the time it takes to process an order, accounting and legal fees, utilities, and repairs.

Operating costs also must be reviewed on an ongoing basis, both to understand the true cost of an item and ensure that employees are using their time productively.

Maintenance

What happens if the equipment breaks or you get a software bug? Does it require a service contract, or are you solely responsible for fixes?

Maintenance, especially for large pieces of construction equipment, can be costly in terms of parts, labor, and unplanned downtime.

Consider the whole picture when evaluating the cost of a particular product:

- How expensive and accessible are the parts?

- What happens when the equipment or program is down?

- What will preventive maintenance cost me?

When it comes to hidden costs, downtime is a doozy. Shutting down production can mean losing thousands of dollars at a time. The problem is that downtime is near impossible to predict.

A preventive maintenance program can help you increase the lifespan of a piece of equipment and reduce the likelihood of surprise breakdowns.

Spend some time discussing preventive maintenance with the vendor. How long is a typical check-up visit? How long does it take to fix common problems? Are parts and labor included?

Additionally, read as many reviews as possible. Find out if other customers experience maintenance issues or if the parts seem costly compared to the equipment as a whole.

In some cases, parts may be hard to find. Weigh costs against the time spent waiting around for a particular order.

Replacement

Replacement costs are the costs involved with replacing a company asset of the same value. Assets include significant purchases such as buildings or large pieces of equipment. Some assets depreciate on a straight-line basis, meaning the cost of an asset is divided by the amount of time that it will be useful. In other cases, depreciation is accelerated, like when you drive a new car off the lot, and it drops in value.

Be sure to consider replacement costs. Many companies don’t generate enough revenue to cover equipment replacements. As such, it’s vital to plan for asset purchases and set money aside for the inevitable.

Disposal Costs

The cost of disposal is another area where costs add up unexpectedly. Disposal costs, or exit obligations, represent the future liability of getting rid of an item down the line. These costs include the losses or gains associated with selling a piece of equipment or those fees related to recycling and hauling away an item that no longer works.

A company might buy a piece of equipment and use it for a few years until they no longer use it or need to upgrade. The machine’s book value can be calculated by subtracting the depreciated cost from the original price. Ideally, you’ll be able to resell the item for at least book value, which accounting would log as a gain. If you have to discount the machine, the below-book sale would be considered a loss.

Receiving and Stocking Orders

We talked about delivery and freight costs, but hidden costs extend to freight processing as well. When you receive an order, you’ll need to pay for your staff or the delivery driver to unload the goods.

Once the items are off the truck, you’ll need to make sure the shipment matches the initial order and note any discrepancies. They must review the product quality, colors, and sizes, to ensure everything matches to PO.

From there, you’ll need to account for the paperwork involved with processing invoices and matching them to POs. If the supplier is disorganized or makes a lot of errors, this may end up wasting a great deal of time. For that reason, it’s crucial that you consistently review supplier performance to make sure they hold up their end of the bargain.

Ongoing Evaluation

Any purchase is subject to hidden costs. Some are administrative tasks or internal labor, while others like surcharges, freight, and installation can increase invoices considerably.

As you consider supplier quotes, discuss these questions before negotiating a contract. One supplier might give you the lowest price but subject you to a whole lot of hidden costs.

The next time you’re tempted to be swayed by a product price, consider what it will cost you before and long after the item is unboxed.