In the supply chain business, newbies tend to think sourcing and procurement are the same. However, that assumption isn’t quite right.

Procurement is the process of the getting the goods and services your company needs to fulfil its intended business model, while sourcing is locating said goods and services.

Procurement covers the end to end process while sourcing refers to the legwork you must do before purchasing goods and services that are essential to your supply chain.

Now, tendering refers to the bidding process and any required paperwork and evaluation.

So, let’s say a company or organization wishes to buy good or services from another company: The buyer will first specify his or her requirements, and from there, interested suppliers can bid for an opportunity to provide raw materials or services.

Where things get confusing is tendering isn’t precisely like bidding on a pair of shoes on eBay. The term is typically reserved for suppliers bidding on a big construction job or a government project.

So, long story short, sourcing is the process by which you find potential suppliers and get a sense of cost. Tendering is the process by which you open your business to bidders who provide a quote for service.

Here are some tips that will have you sourcing and tendering like a pro in short order.

Let’s dive on in, shall we?

[content_upgrade cu_id=”3554″]Set up your own sourcing and tendering process–click here to download the free guide.[content_upgrade_button]Click Here[/content_upgrade_button][/content_upgrade]

The Sourcing Process Explained

The sourcing process sounds pretty straightforward. It’s a gathering phase. Still, there are a few steps you don’t want to skip over.

Analyze the Spend Category

Preparedness is vital in the procurement business. At this stage, you need to make sure you know every detail about the spend category in question. So, if you plan to buy a massive quantity of cardboard boxes, you need to know everything about the cost, box thickness, minimums or customization options.

Here, you’re not making any significant decisions; you’re just learning more about the category so that later when you’re looking at different suppliers, you’ll know what price range to shoot for or get a sense of expected lead times.

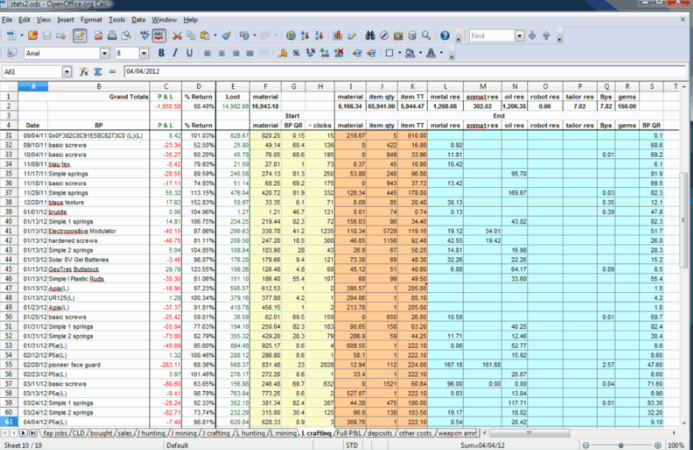

Additionally, it is wise to document all of this data into one cohesive spreadsheet for later reference, like this:

Analyze Your Market

In this phase, you’ll study the costs of the product or service, and from there, analyze the suppliers’ risks and opportunities compared with other players in this space. In addition to the cost of raw goods, you’ll want to compare costs like transportation, minimum order quantity and labor.

Develop Your Sourcing Strategy

Deciding where to buy while minimizing risk and costs is how you develop a strategic sourcing strategy. So, start considering the following when looking at specific suppliers:

- How competitive is the market for suppliers?

- Will doing business with any of the prospective suppliers damage existing vendor relationships?

- What are the odds of securing a better price?

Answering these questions will help form your strategy and narrow your search.

Tracking and Benchmarking

Tracking the commodities in each spend category is an ongoing process. Yes, sourcing is the precursor to tendering and making a purchasing decision; but, it is also the beginning of a cycle. Markets change all the time, and you’ll need to continually research and analyze to ensure you’re getting the most for your money.

A Look at Tendering

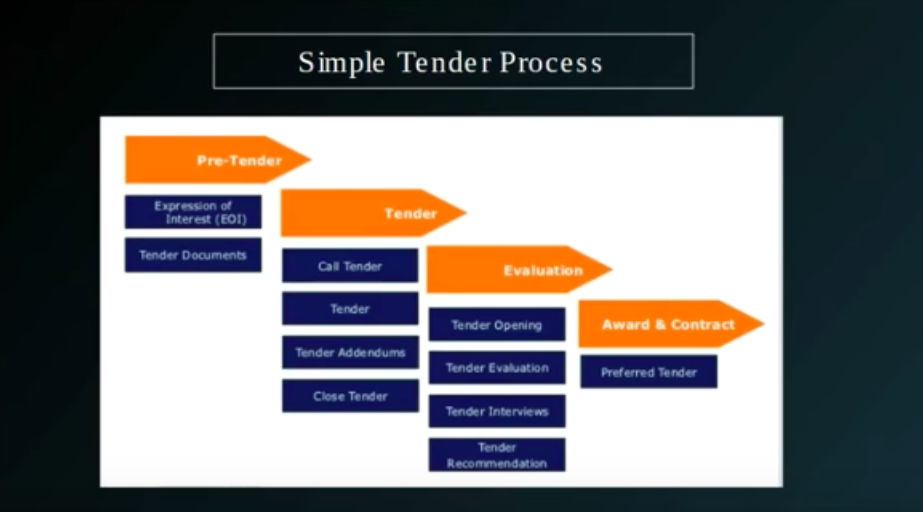

The tender process involves a few different stages. Tendering picks up where sourcing leaves off. Where sourcing was about gathering data and compiling information, tendering is where you’ll start putting that data to work.

[bctt tweet=”Where sourcing was about gathering data and compiling information, tendering is where you’ll start putting that data to work. ” username=””]

This is a multi-step process that ranges from negotiations to evaluations to awarding contracts to the best supplier for the job.

We should start by first explaining that the tender process differs by organization and project.

- What is the scope of the project?

- Are you working in the public sector or the private sphere?

- What kind of resources do you need?

Also, if the tendering organization has a policy in place, it may affect the procurement process. In some cases, a tendering team might include several people or just be an army of one.

Pre-Tender Stage

What is the outcome you hope to achieve?

Here, you’ll work on gathering documents. You’ll need to produce a tender document and an expression of interest. The specification is essentially a tender document — what are you trying to get out of the process. It’s not technical, it needs to focus on the output of the tender.

You can start reaching out to potential buyers by issuing any of the following documents:

Request for Information—This is an open inquiry seeking general information and understanding of potential suppliers. Here, you might ask specific questions about facilities, motivations, finance and scope of offerings.

Request for Bids—Less formal, used for lower-cost goods and services. If this is the route you take, you might choose to skip the more formal request for tender.

Request for Tender (RFT)—This document outlines what is required. The RFT is an invitation for businesses to respond to that need and provide the best value for your money. Here, you’ll outline your criteria and offer instructions to interested suppliers.

The tender document itself includes the tender invitation, the commercial specification and the technical specification.

For example, if you put a tender out for X amount of vans and mopeds, you run the risk of failing to provide the best transportation solution. Instead, you should ask for solutions that bring the most cost-effective products.

In some cases, the supplier may opt to create a pre-qualification questionnaire. This will allow you to sift through suppliers before going through the full process.

This stage could consist of a quick phone interview or a questionnaire.

Tender Opening

The invitation to tender will be issued to a list of the suppliers that made it through the pre-qualification round. This letter will include the following:

- Business requirements

- How to apply

- Due date (give six weeks minimum)

- Process for selection

- Performance metrics

- Relevant contacts, who to contact with questions

- Request for quote

Evaluation and Recommendation

Evaluation starts at the beginning of the process. It’s outcome-oriented and ongoing. You’ll want to create an evaluation document that is objective and allows different stakeholders to evaluate each solution and compare them fairly and accurately.

Things to consider:

- Are your goals aligned with the future partner? Does the supplier understand and support your corporate goals?

- Is the bidder the appropriate contact? Will you be working with this person long-term? If not, who will be involved?

- Is the supplier an expert in the industry? Do they know the market? Are they connected with other suppliers you could use in the future?

- Is the supplier an innovator? New ideas and solutions set bidders apart from the competition and can be a real asset to your company.

- Risk management—Does the bid address things like what would happen in the event of a disaster? What are they doing to ensure solutions are carried out as planned?

- Are they responsive? Does the bid communicate a willingness to adapt to client needs? Are they flexible?

After you’ve gone over the evaluation process and eliminated some suppliers, you need to provide feedback for those who fall out of the running. Recommendations should be objective, detailed and informative.

Those who don’t meet the criteria need to know why the fell short. Organizations that fail to provide feedback risk getting low responses for future tenders.

But, the recommendation doesn’t need to be a big to-do. Write a letter or make a quick call to provide feedback. This isn’t the equivalent of a form letter rejection. Instead, it’s an opportunity to help suppliers grow and build relationships with people in the industry. You never know, you could work with these folks down the road.

Tender Interviews and Negotiations

After narrowing your search, you and your team will hold interviews. Here, bidders will present solutions and answers to any questions. At this stage, you can also start the negotiation process.

The first round of the negotiation process will consist of suppliers asking for clarifications and more detail where needed.

A smart strategy may consist of multiple rounds of negotiations, whittling down your list of suppliers to the top contenders. The final decision is usually done by the whole team and signed off by senior stakeholders–i.e., CFO or procurement manager.

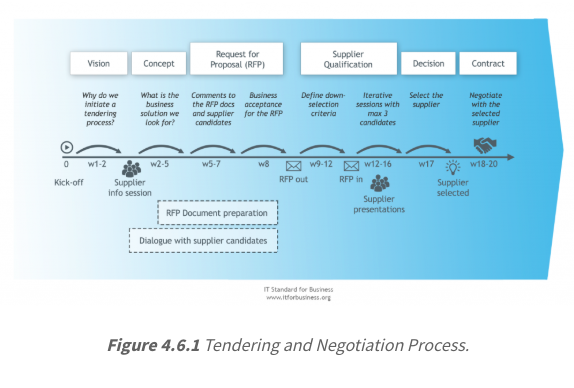

Below, we’ve included a graphic showing the move from initial planning to negotiation. It’s worth pointing out that negotiations can happen during this final qualification stage, as well as right before the supplier signs the contract.

Award and Contract

Alright, we’re in the final stretch out. Once you’ve selected your winning supplier, there are some things you’ll need to do.

If the bidder accepts, they will then be asked to sign a contract to formalize the offer. So, you’ll need to have a contract ready to go. Before sending along the forms that will make things official, you’ll want to look over the proposal again to see if you need to make any changes to the terms.

If there is a delay in the awarding process, you’ll also want to touch base with the supplier to ensure they’ll still be able to deliver on what was promised in the initial bid.

Who are the People Involved in this Process?

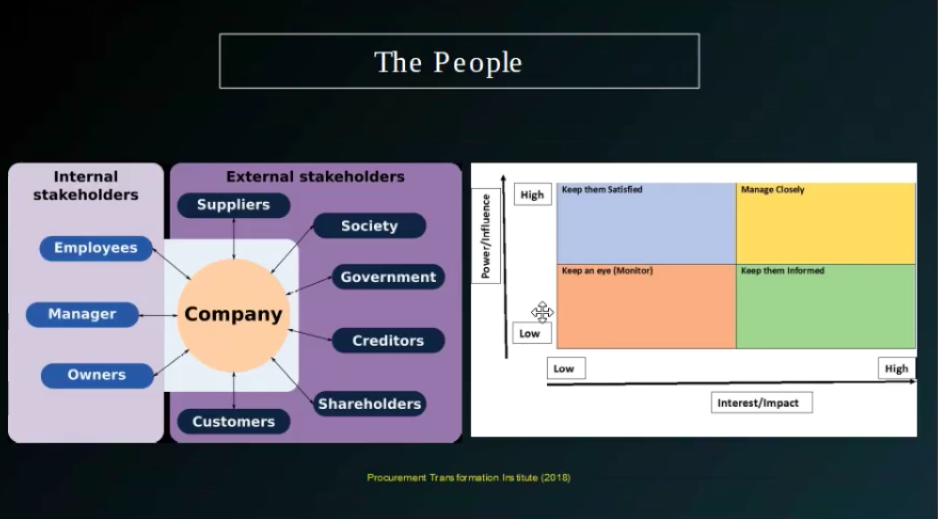

Internally, you have the employees, the manager and the owners. Employees play the most significant role. You need to have buy-in at this level—if there’s an issue with the policy, you risk confusion or disgruntled employees down the road.

If you’re putting out a call for tender, non-procurement folks need to be onboard, too. For example, marketing needs to be aware of what’s going on so they can adjust outgoing communications — customer service, accounting, everyone plays a role.

Externally, you have suppliers, government, creditors, shareholders and ultimately, customers. Anyone you work with, report to or serve is a stakeholder.

[content_upgrade cu_id=”3554″]Ready to do it yourself? Click here to download your free guide to creating a sourcing and tendering process.[content_upgrade_button]Click Here[/content_upgrade_button][/content_upgrade]

Conclusion

While the tendering process can seem intimidating at first, having a process in place is your best defense against disorganization.

Start by making a one-page procedure that’s appropriate for your organization. Over time, you’ll evolve your process, but working through the kinks is just part of the learning process. Most importantly, all stakeholders in your organization need to be on the same page–you need to know who is involved in negotiations, sourcing and putting out the request for tender.

Get Top Rated Purchasing Software & Replace The Purchasing Book.