Contractors often finish out the year with less money than they expected. When you think about the moving parts of a large-scale construction project, it’s no surprise that little things eat into your bottom line when you neglect a bit of budget planning.

Though easier said than done, we cannot overstate the benefit of creating a budget and tracking your spend against the goals.

Here, we’ll look at budget planning and how it helps construction companies gain more control and visibility.

[content_upgrade cu_id=”4023″]Five ways to evaluate supplier quality — subscribe here to get your free checklist[content_upgrade_button]Click Here[/content_upgrade_button][/content_upgrade]

Why it’s so critical for construction teams to have a detailed budget in place

A budget isn’t busy work. It’s a strategy that lays out the operational and financial goals of your company. Creating an effective budget will help the organization align purchasing activities to the organization’s overarching goals.

It also allows project managers to understand how any changes–be it increased prices or a pallet of damaged wood–will impact a company’s financial goals.

This information is critical, as it lets companies find ways to compensate for added expenses in real-time. And managers can communicate changes to finance, accounting, and project leads.

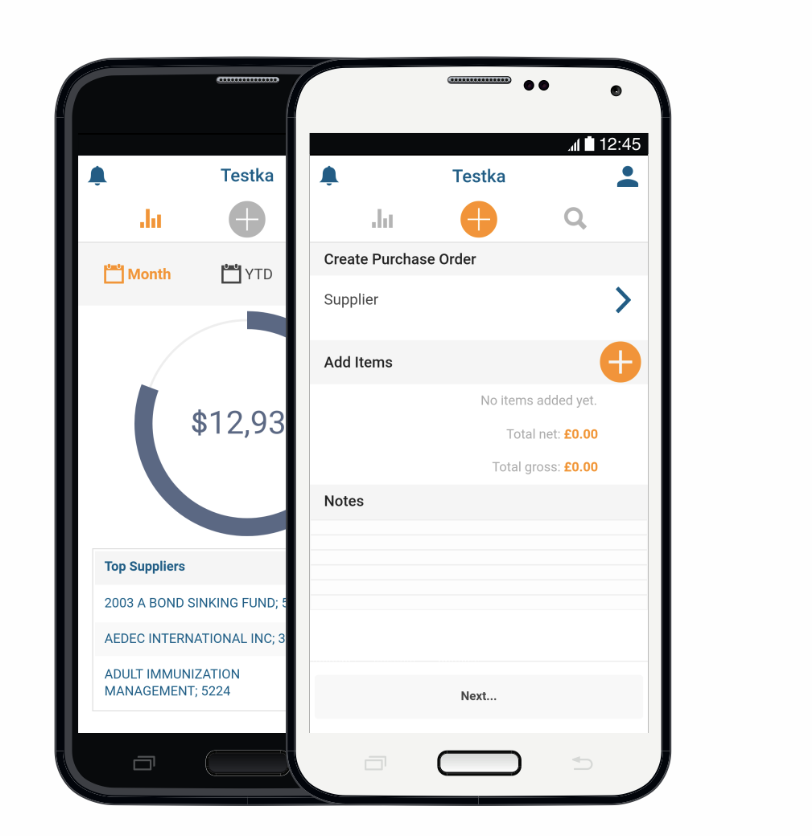

Digitizing this process also makes things much easier. ProcurementExpress.com, for example, allows users to view a project’s budget against incoming orders, from any device. So, if a contractor submits an order for more screws from a remote site, budget managers will receive a notification and can see if there are any pending orders for that item before pushing it through.

Budget Planning Begins with Some Research

Market and price fluctuations will dictate how much your company earns. However, you can get a sense of what to expect by reviewing your past three years’ financial performance.

This process will involve gathering your balance sheets, tax info, income reports, and cash flow statements.

The next step is learning more about all of the factors that can compromise your ability to stay on budget. Meet with a financial advisor, study construction data, and economic projections. While nothing is a sure thing, the more “expert” information you have, the more accurate your budget.

Meet with your team and discuss market opportunities as they relate to the budget, booked projects, and past performance.

It’s smart to set separate budgets for each project so that you can track spending by the client or as an organization-wide effort. This will allow you to identify which projects are most profitable and which ones went way over budget.

Our software allows you to set budgets within the tool, which gives all stakeholders the ability to see where money is going, as compared to the established goals.

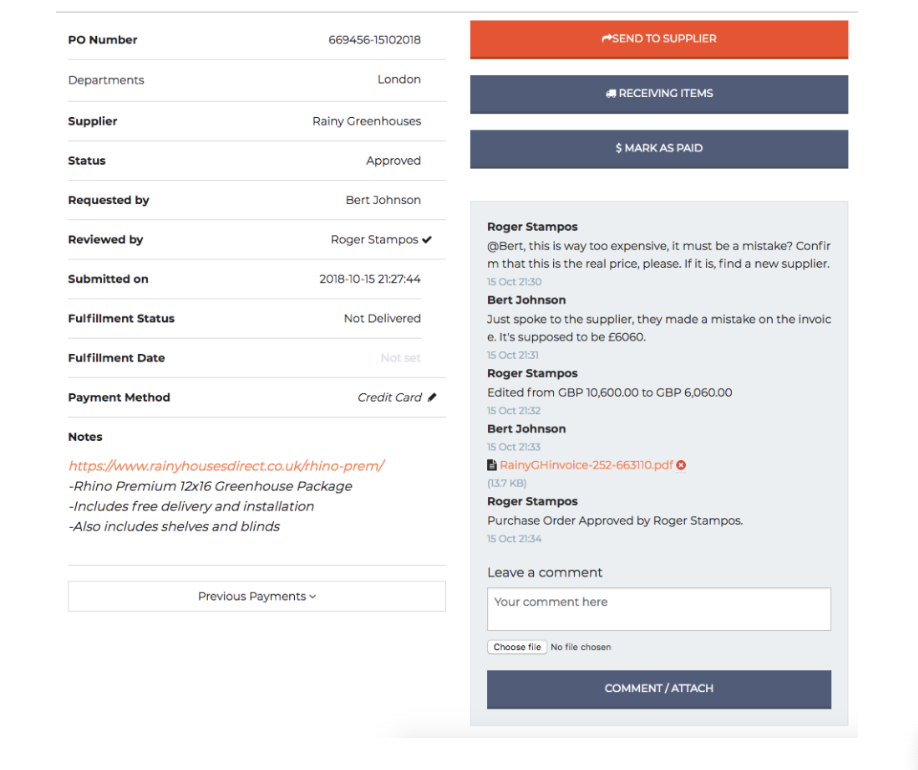

Additionally, you can stop orders from going through that contain mistakes or dramatic increases. In the below example, you’ll see that budget management is an ongoing conversation.

Build in a Contingency Plan

Most projects have some unexpected things that could increase costs. In most cases, the real cost is always higher than the estimate, and it can be difficult to predict.

Instead of overestimating the costs on your initial quote, build some padding into your budget for these likely increases. While that cash reserve does not account for supplies or permits, teams should assume that they’ll spend that extra cash.

If everything goes as planned, you’ll have additional capital to work back into the business.

Evaluate All Costs Needed for Each Project

Construction projects are quite expensive. Prepare for overruns and unexpected bumps along the way. By adding a tool like ProcurementExpress.com to your strategy, you’ll be able to assess your resources against the items needed to finish a project.

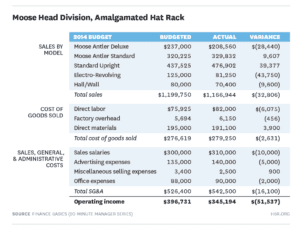

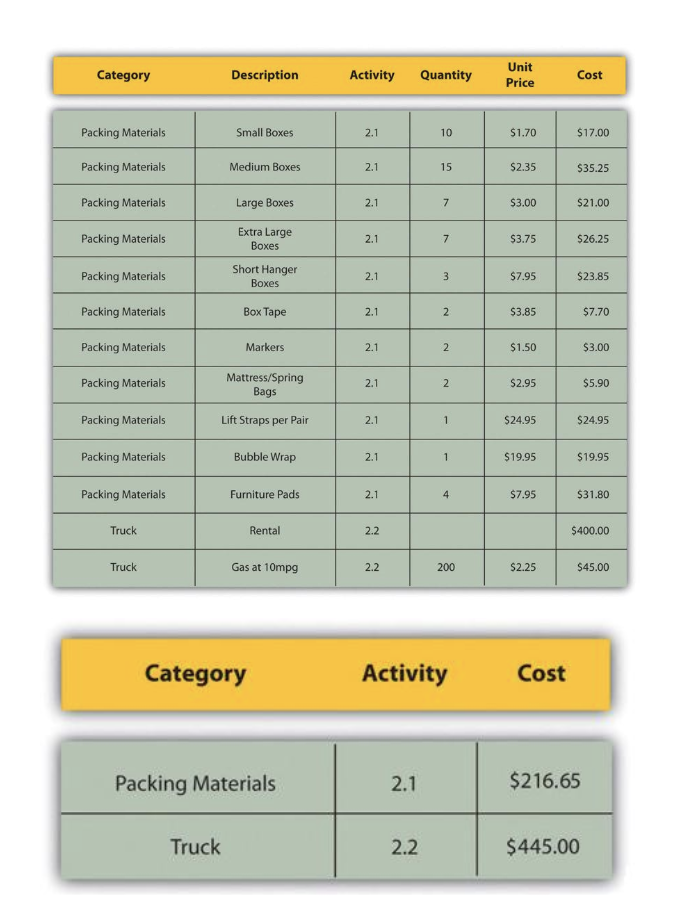

Project managers must get ordering right, as materials represent a considerable expense for construction companies. As such, any area with more control spells more profits. Make a list like the example below to get a sense of how much everything from wiring to permits, labor, and wood will cost.

To stay on top of your supply management, implement tight controls with every budget. If you purchase materials too early, you may deal with charges incurred from excess materials—this could mean throwing out damaged or deteriorated materials or charges incurred for storage.

Conversely, if you fail to order enough materials, you’re stuck waiting for orders to come through—or you might not be in a position where you can get the best pricing or highest quality item.

This is an area where technology can make a considerable difference. For example, you can pull up a record that shows how much you spent on concrete last year and from there start looking for opportunities to save. Have costs risen? Is it time to look for a new supplier?

Over time, your budget planning process won’t involve much digging around in the file cabinet. Instead, project managers and finance teams can review a series of cloud-hosted POs to make more accurate predictions about costs.

In addition to labor costs, your contingency fund, and all of the materials involved in your construction project, you’ll also need to account for soft costs and site costs.

Draft it Out

Make a rough draft using the research documents you’ve gathered in the initial stage. While the rough draft won’t account for everything, it will show various costs like goods and labor, as well as sales trends, marketing costs, and operational costs.

The benefit of drafting out your budget before solidifying key details is having a real roadmap of both your costs and cash flow.

Even the smallest construction projects are composed of hundreds of moving pieces, from site costs and permitting, to the actual line items.

Once you’ve put this together, meet with your executive team to make any changes to the budget. Then, take those notes back to the drawing board and start developing the final product.

Let’s Get Digital

[bctt tweet=”Between unforeseen costs and permit issues, there’s no excuse for skipping a detailed budget planning process.” username=””]

For best results, you’ll have all stakeholders on the same page, so nothing slips through the cracks. ProcurementExpress.com allows you to add your budget to the system, a list of preferred vendors, and a record of all orders. The benefit of keeping this information in the cloud is seeing everything in real-time.

With paper records, things can get lost. A worker might place an order and forget about it. Or, your accountant may never see the original PO during the receiving process. These may seem like small things, but that lack of oversight adds up to lost profits and wasted time.

Budgeting also doesn’t stop after a project has run its course. It’s an ongoing cycle that requires constant review. Comparing goals with actuals allows management to make corrections along the way—keeping an eye out for extra expenses that compromise profits and pumping the breaks by cutting costs elsewhere.

Try our free procurement efficiency grader and get insights into how you can improve to make your business become more efficient.